Processing facilities

Our Site

- 5.5 acres

- Over 60 employees

- 6000 square metres warehouse

- Centrally located in Chesterfield, close to the heart of steelmaking

Gould Alloys modern site is equipped with the latest technology to meet the specific needs of all its customers. The facilities enable customers to source products and components 'near to net weight' and 'near to size' for maximum efficiency and cost-effectiveness. Gould can also arrange independent heat-treatment and/or testing through approved routes, thereby guaranteeing that maintenance of traceability. In addition, Gould is happy to process customers' free issue material as well as arrange buy-back or reprocessing of customers' items.

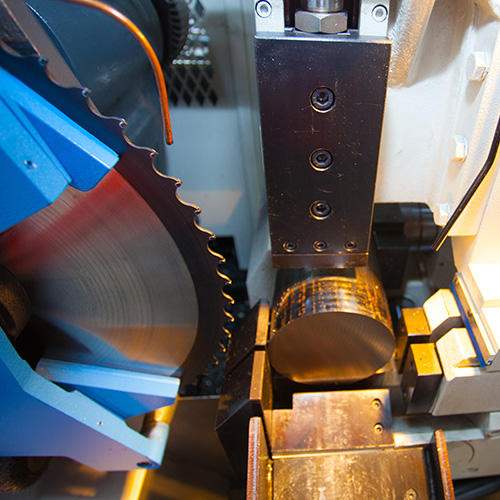

Bar Saws and Billeting

7 CNC band saws, maximum section 530mm x 530mm

Plate and Sheet cutting

Gould Alloys provide a range of cutting facilities for sheet and plate to meet all customer requirements, including guillotine, plate sawing and profiling plus our particular speciality, water jet cutting.

Machining

Gould Alloys provides first stage/rough machining to customers' drawings.

- Milling - vertical & horizontal

- Lathe - conventional & CNC

- Chamfering machine

PMI Tester

Positive material identification using the hand held Niton XLt.800

Other Testing

Independent testing through approved routes

Heat Treatment

Independent heat treatment through approved routes